6000bph Full Servo Plastic Pet Blow Molding Machine/Pure Mineral Water Bottle Blowing Making Machine

6000bph Full Servo Plastic PET Blow Molding Machine/Pure Mineral Water Bottle Blowing Making MachineModel: Q6000 TECHNIC

Description

Basic Info

| Model NO. | Q6000 |

| Certification | CE, ISO9001:2008 |

| After-sales Service | One Year |

| Component Brand | Siemens Mitsubishi |

| Voltage | According to Customer Request |

| Driven Type | Servo Motor |

| Bottle Material | Pet |

| Cavity | 4 |

| Theory Output | 6000PCS/Hr |

| Max. Volume | 2L |

| Power | 43kw |

| Size of The Machine | 4.1X1.7X1.9 (M) |

| Weight of The Machine | 4000kg |

| Transport Package | Wooden Package or as Customer′s Request |

| Specification | ce iso |

| Trademark | eceng |

| Origin | Zhangjiagang Jiangsu |

| HS Code | 8477300000 |

| Production Capacity | 6-8sets Per Month |

Product Description

6000bph Full Servo Plastic PET Blow Molding Machine/Pure Mineral Water Bottle Blowing Making MachineModel: Q6000

TECHNICAL PARAMETER

| Item | Q6000 | |

Bottle type specification | Cavity | 4 |

| Output(PCS/HR) | 6000-6500 | |

| Max. Volume (L) | 2L | |

| Bottle mouth maximum overall diameter (mm) | 28-38mm | |

| Bottle biggest diameter | 100mm | |

| Bottle maximum height | 330mm | |

Power specifications | Light tube quantity | 32PCS |

| Light tube power | 1.25kw | |

| Maximum heating power | 40kw | |

| All electric machine installation | 43kw | |

| Actual consumption | 21.5kw | |

Air pressure specification | Work pressure | 7-9kg/cm2 |

| Low-pressure gas consumption | 1600LTR/min | |

| Blow bottle pressure | 25-35kg/cm2 | |

| Higher -pressure gas consumption | 3000 LTR/min | |

Frozen water specification | Work pressure | 5-6 kg/cm2 |

| Temperature range | 10 | |

| Consumption | 8000kcal/hr | |

| Frozen water flow | 88LTR/min | |

| Machine specification | Size of the machine | 4.5X1.6X1.9 (m) |

| Weight of the machine | 3.5ton |

Q series linear bottle blowing machine adopt servo control system, with stable and reliable structure, high speed, stable, simple maintenance, flexible and convenient mold matching etc, which can meet needs of continuous production. Use microcomputer touch screen controls and adjusts temperature, make temperature adjustment of blow molding different bottle type simple. Servo transmission system, high positioning accuracy, fast speed, good stability and reliability, no need air source, energy saving, low maintenance cost.

Detail Photos:

Auto-loader improves working efficiency, accurate transportation, reliable and durable, raw materials are completely free of moisture, pollution, foreign matter, and loss during feeding process. Realize transportation process of feeding process, avoid danger of high-altitude feeding, reduce labor intensity and increase production efficiency.

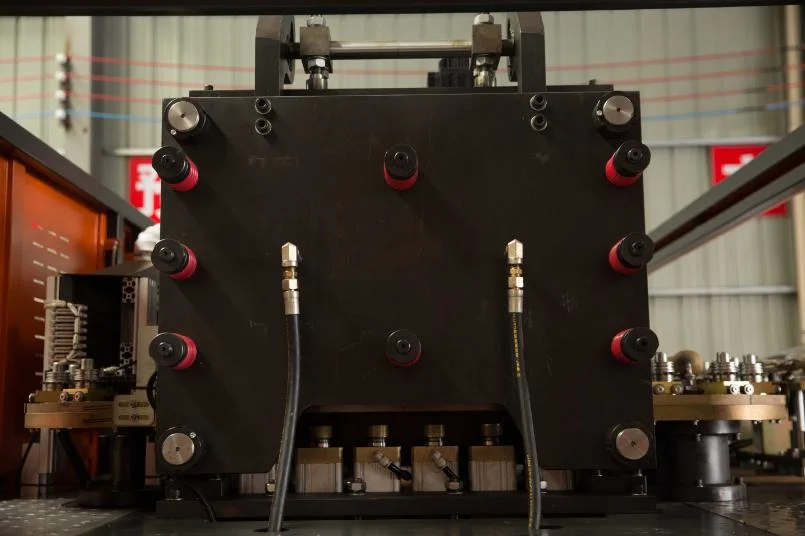

New clamping system, upgraded on the basis of the original ones, increase mould clamping speed and output, greatly reduce mold clamping noise.

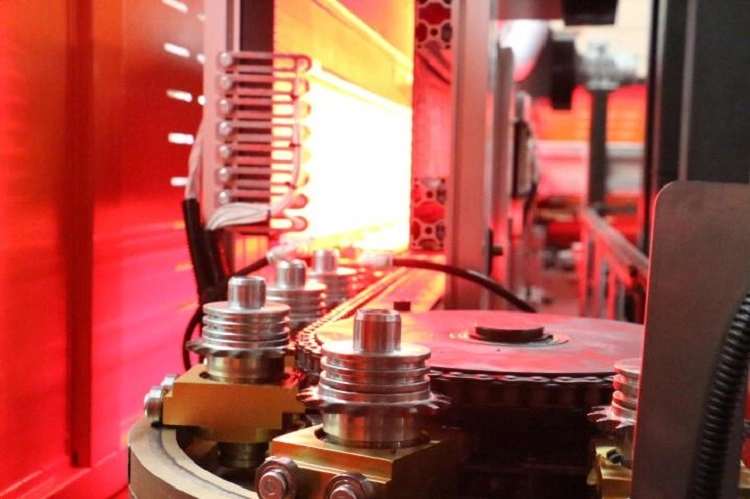

Adopt infrared lamp heating, strong penetration, preform rotation heating, track revolution, heating evenly, fast and reliable; Heating lamp, reflector width and height can be adjusted to suit preform heating of different structure, with automatic temperature-removal device to ensure the constant temperature of oven.

Q6000 bottle blowing machine adopts advanced microcomputer PLC control system, stable performance; Servo transmission system, high positioning accuracy, fast speed, stable and reliable.

FAQ: Q1: Are you a trading company or a manufacturer? A1: We have our own factory for 10 years, will try our best to provide you service. Q2: What's your guarantee or the warranty of the quality if we buy your machines? A2: We offer you high quality machines with 1 year guarantee. We will give u spare part free in 1 year, Life long after service. Mean while, our engineers can go to your factory assist you installing and testing machine to normal working condition. We also have a technical team support for after service. Q3: When can I get my machine after I paid? A3: We will deliver the machines on time as the date we agreed both side. Q4: How can I install my machine when it arrives? A4: We will send our engineer to your side as soon as you get all your machines ready, for testing and teaching your technicians how to run the machines. Q5: What's the delivery time? A5: 45 days after the T/T deposit or L/C. Q6: Where is your factory located? A6: Our factory, near Shanghai & Ningbo port, is located in Zhangjiagang, Jiangsu. Q7: How about quality control in your factory? A7: " Quality is the key point, do what customers need"Eceng machinery factory focuses on quality, quality control from beginning to the end. Every piece of goods is tested strictly before packing and delivery. Q8: Do you provide bottle blow mould and air compresor? A8: Yes, we provide complete system and you will no need to find the suitable air compressor and chiller...etc...Q9: What is the language of the PLC and touch panel? A9: Don't worry, we will translate the language in English, Spanish or any other language, to make sure you will have an easy operation. Q10: Do you have reference project? A10: We have reference project in most countries, If we get the permission of the customer who has brought the machines from us, we can tell you their contact information, you can go to visit their factory. And you are always welcome to come to visit our company, and see the machine running in our factory, we can pick you up from the station near our city. Contact our sales people you can get video of our reference running machineQ11: Do you have agent and after-service stations? A11: So far we have agent in Thailand, Vietnam, Columbia, Indonesia. Welcome to join us! Q12: Do you provide customized serviceA12: We can design the machines according to your requirements(material, power, filling drink, different bottle neck and bottle design, logo design and so on), give you suggestions for your unique needs.

Warmly welcome to visit our factory!

Our Contact

Send now