Automatic Multifunction Self-Adhesive UPS DHL TNT Honeycomb Kraft Paper Padded Buffering Foam Bubble Express Courier Mailer Bag Envelope Making Machine

Description

Basic Info

| Paper Thickness | Thin Paper |

| Web Working Width | 600mm |

| Mould Effective Width | 500mm |

| Unwinding Diameter | 0-1200mm |

| Unwinding Stand Weight | 1ton(Can Make More Bigger) |

| Unwinding Shaft | 3 Inch Inflatable Air Shaft |

| Rewinding Shaft | 1inch/1.5inch/2inch/3inch |

| Machine Size | 2620*1640*1160mm(Lwh) |

| Machine Weigth | 1000kgs |

| Power Supply | 380V 3 Phases 5 Wires |

| Air Pressure | 6-8kg/C Square Meter |

| Transport Package | Wooden Box |

| Specification | 2620*1640*1160mm |

| Trademark | koxte |

| Origin | China |

| HS Code | 8441100000 |

| Production Capacity | 20set/Month |

Product Description

Product Description

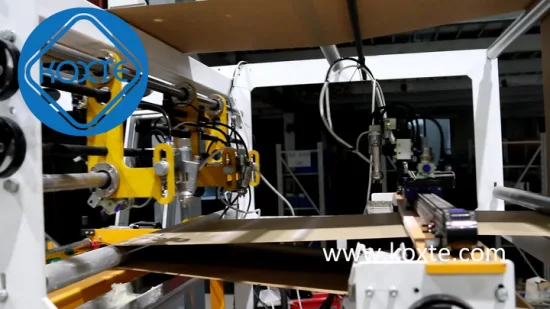

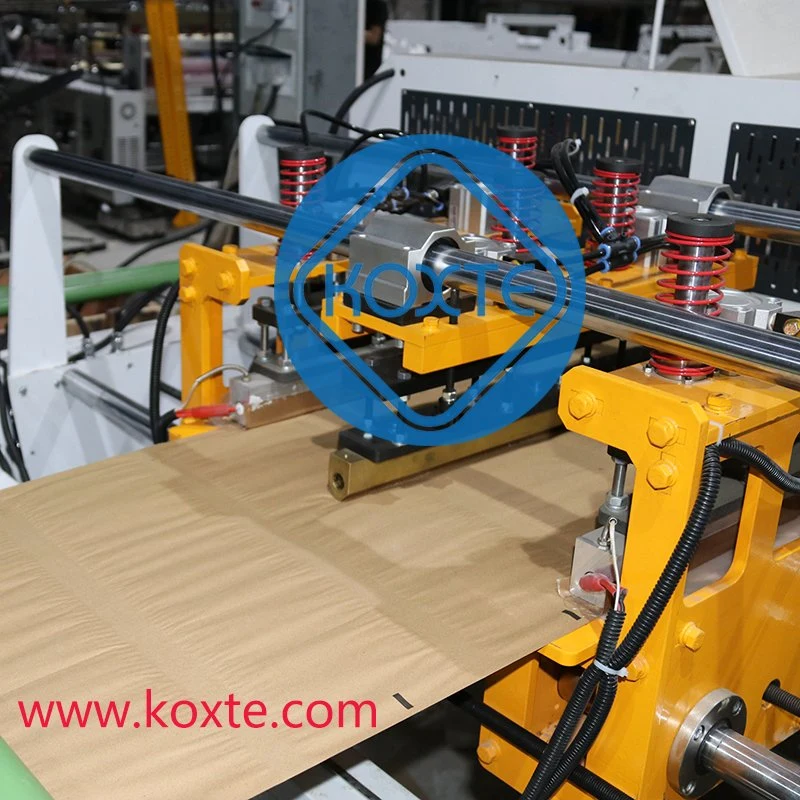

1. This machine is special designed for making bags which laminate the Kraft paper and Honeycomb paper by glue.

2. Bag making method: Fixed the Kraft paper and honeycomb paper (by stretching) into two layers of Kraft paper by fixed point glue spraying method, and then by, second gluing, folding and cutting into a environmentally cushion bag which used in express industry.

3. This machine uses multi point advanced motion controller technology. It is controlled by computer program from film unwinding to cutting. This machine is a high-quality, easy-operational and professional one to make good-looking a, durable and environment-friendly bags.

Detailed Photos

Honeycomb paper is eco-friendly and cost effective alternative for plastic bubble wrap cushioning.It is easy to stretch,more soft and flexible,provide cushion protect without surface scratch.Finished products from this machine can be used to pack fruits,flowers,glassware etc.

Product Parameters

| Suitable bags | profession0al designed for honeycomb cushion bags. |

| Mechanical speed | 1000-1500pcs/hour(Note: the actual speed of making bags may differ according to the size of bags) |

| Max width of bag (Height of bag) | One line: 550mm (including the envelope flap) Double line: 300mm (including the envelope flap) |

| Maximum length of bag (width of bag) | 500mm |

| Maximum width of unwinding | Kraft paper: 1200mmX2, honeycomb paper 500mmx4 |

| Maximum diameter of unwinding | Kraft paper 1000mm, honeycomb paper 500mm |

| Machine weight | 17000KGS |

| Overall Dimension | 30000X2300X2400mm |

| Power required | 60KW |

| Voltage | 380V 50Hz Three Phase Five wire |

Company Profile

Wenzhou Kxite Machinery Technology was established in 2010 and is committed to the development and production of environmentally friendly paper bag equipment. Provide customers with professional technical consultation, installation and commissioning, training and operation, and a whole set of professional service system.As a manufacturer of paper bag machines serving the world, we always put quality innovation first, from R&D design, parts procurement, assembly production, quality inspection and evaluation, sales to after-sales and other systems, to truly meet customer needsPrecise sales, think what you thinkBy inspecting the global paper bag production status, comprehensively considering the suggestions of printing and packaging industry veterans, according to the actual needs of different customers, we design and produce a variety of configuration models, allowing customers to choose flexibly.Excellent R&D managementWe have an excellent R&D design team and excellent management talents in the packaging industry. We fully understand the actual needs of the packaging industry, ensuring that every piece of equipment we manufacture can be affirmed by customers and create greater benefits.After-sale guaranteeProvide customers with comprehensive and timely after-sales service and a sense of service in the end.

| Sharp bottom paper bag machine | Window type paper bag machine | Flat Rope Handbag Paper Bag Machine |

| Double folding bottom paper bag machine | Square bottom paper bag machine | Round flat rope integrated paper bag machine |

| paper bag making machine | Round Rope Handbag Paper Bag Machine | Multifunctional square bottom paper bag machine |

| Koxte paper bag making machine | Kxite paper bag making machine | Paper food bag making machine |

| Paige bag paper bag machine | Square bottom window paper bag machine | Siamese printing paper bag machine |

| Square bottom Siamese printing paper bag machine | Pointed bottom Siamese printing paper bag machine | KFCpaper bag making machine |

FAQ

Pre-sales issues

How to answer technical guidance?

For some customers who need non-standard equipment, we will communicate with the company's relevant technical personnel according to the customer's specific requirements, taking into account the technical feasibility and production costs, and give customers solutions.

How to recommend products?

We can also provide non-standard equipment production and new product development services according to customer requirements. According to the customer's picture of the paper bag to be produced, the purpose of the product to be purchased, the environment, the purchase volume and other related conditions, we will recommend several cost-effective products for the customer to choose.

How to make a quotation?

Based on our company's research and development costs, production costs and customer purchases, we conduct calculations to determine the price of the product.

Problems in sale

About payment

After signing the contract, 30% of the total payment will be paid in advance, and the factory will accept the payment and pay the full amount of the machine for delivery.

About delivery time

About 90 working days after receiving the deposit (non-standard machine), the factory will re-decide whether to change the delivery date when the order is confirmed. The standard machine is generally within 60 working days after receiving the deposit.

Order tracking

After the customer places an order, our company will send professional personnel to track the order and regularly report the production progress to the customer. Customers can check the order status on the official website (delivery query).

Product testing

During the production process, our company will adopt strict inspection process to ensure product quality. Through internal inspection, we ensure that the components produced by our company meet the technical requirements; through external inspection, we ensure that the components produced by our company are not subject to quality problems; and then pass the whole machine inspection to ensure that the mechanical equipment meets the technical production requirements .

Product packaging

Before the product is shipped, it will be packed in a strict vacuum plus bottom tray (wooden tray or steel tray)

Product Transportation

Products are generally shipped from Ningbo Port, China to the destination port by sea.

After sales question

Shelf life/warranty period of the product

The product warranty period is generally one year, and our company provides lifetime maintenance services. If the machine has quality problems, our company will help the customer to solve it through the following ways: a. Send spare parts to the customer. b. Remotely assist customers in maintenance. c. Notify our agent company to send personnel to the customer's factory for maintenance. d. Our company directly dispatches relevant personnel to the customer's factory for maintenance.

About transportation damage

In the process of product transportation, if product damage occurs, it is determined that our product packaging and reinforcement work is not in place, and our company will bear the corresponding losses.

About machine maintenance

We will contact customers on a regular basis on how to maintain and maintain the machine. For domestic customers, we will have a master to provide on-site service.

Problems during use

If there is any problem in the process of using the product, the customer can directly call or send an email to our after-sales department (24-hour hotline). The personnel of our department will respond immediately and make a decision on the response measures within 24 hours.

Our Contact