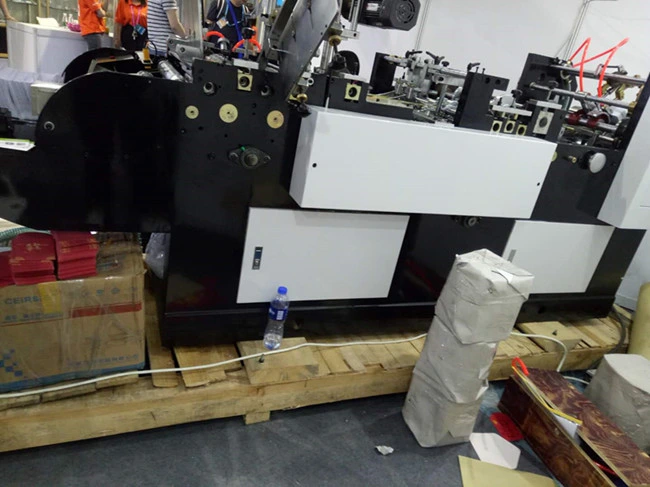

Automatic Paper Envelope Pasting Making Machine for Sale

Overview Package size per unit product 330.00cm * 100.00cm * 130.00cm Gross weight per unit product 1200.000kg Product D

Description

Basic Info

| Model NO. | ZM-390A |

| Bag Type | Paper Envelope Making Machine |

| Characteristic | Forming |

| Computerized | Computerized |

| Speed | High |

| Width | 176*230mm |

| Size and Shape | 4100×1900×1600 |

| Long | 80*80mm |

| Weight | 1200kg |

| Material | Automatic Western Type Paper Envelope Making Machi |

| Usage | Automatic Western Type Paper Envelope Making Machi |

| Item | Paper Envelope Making Machine |

| Paper Weight | 70-200GSM |

| Air Pump Power | 3kw |

| Power | 1.5kw 380V 50Hz 3p |

| Transport Package | Wooden Case |

| Specification | 3.23*0.97*1.27m |

| Trademark | ZOMAGTC |

| Origin | China |

| Production Capacity | 300 Sets/Month |

Packaging & Delivery

Package size per unit product 330.00cm * 100.00cm * 130.00cm Gross weight per unit product 1200.000kgProduct Description

| Machine Description |

| Machine Parameters |

| Model | ZM-390A |

| Chinese type envelope size | 110*230mm-176*230mm |

| Western type envelope size | 80*80mm-176*230mm |

| Speed | 12000pcs/h |

| Paper weight | 70-200gsm |

| Air pump power | 3KW |

| Power | 1.5KW 380V 50HZ 3P |

| Weight | 1200KG |

| Dimension | 3.23*0.97*1.27m |

| Machine Feature |

| 1. | It adopts air suction type bottom paper-extracting system to supply paper without a pause. |

| 2. | With compulsive setting system and horizontal pre-pressure, vertical pressure-; loading parts can assure product accuracy at high speed and rotary paste suits to any purpose. |

| 3. | Completed with air absorbing type roller barrier folding system, it may work steadily at high speed. |

| 4. | Collection section has electronic count and group system in order to pack finished products. |

| 5. | Driving system follows synchronization and rotation to reduce noise. |

Our Contact

Send now