Automatic Single/Double PE/ Water Based Paint Paper Cup Forming Machine

Description

Basic Info

| Model NO. | ZBJ-09 |

| Logo Printing | Without Logo Printing |

| Certification | CE, SGS |

| Customized | Customized |

| Condition | New |

| After-sales Service | Engineer Service |

| High Speed | 80-100PCS/Min |

| Machine Robotic | Machine Hand |

| Paper Cup Machine Size | 2800X1600X1700mm |

| Paper Cup Machine Weight | 3000kgs |

| Ststem | Shaft and Gear System |

| Cup Bottom | 40-52.8mm |

| Cup Height | 35-92mm |

| Cup Top Size | 55-82mm |

| Transport Package | Wooden Case |

| Specification | 2200*1150*1700mm |

| Trademark | LIFENG |

| Origin | Zhejiang, China |

| HS Code | 8441309000 |

| Production Capacity | 55sets/Month |

Product Description

Machine Description:

LF-90 MID-speed paper cup forming machine is a multi station high-speed automatic machine producing both single and double PE coated drink cups, ice cream cups through continuous process of automatic paper feeding, sealing, oil injection, bottom cutting, heating, knurling, curling and stacking. The machine adopting hot air system, PLC control, servo motor driving, full-automatic failure warning, counting, detection, stopping, etc.

| Name | Middle Speed Paper Cup Machine | |

| HS Code | 8441309000 | |

| Model | LF-90 | |

| The machine includes: Finished cup Collect System | ||

| Paper cup Size | TOP DIAMETER=70mm-95mm | BOTTOM DIAMETER=48mm-63mm |

| CUP HEIGHT=46mm-100mm | BOTTOM DEPTH =5mm-10mm | |

| Raw Material | One-side or two-side PE coated paper(Singe PE or Double PE coated paper) | |

| Speed | 90-100pcs/min | |

| Speed of 20 hours stable running per day | ||

| Suitable paper weight | 190-350gsm | |

| Voltage supply | 380v50hz 3-phase*If user's voltage supply is different, please inform us in advance. | |

| Working Air Source | Air pressure 0.5-0.8Mpa, 0.4m3/minUser should buy Air Compressor | |

| General power | 9kw | |

| Net weight | 2300kgs | |

| Measurement (mm) | 2300*1250*1800 | |

| Cup Side Sealing | Ultrasonic sealing | |

| We can customize machine and mold according to customer's requirement. | ||

Machine advantage:

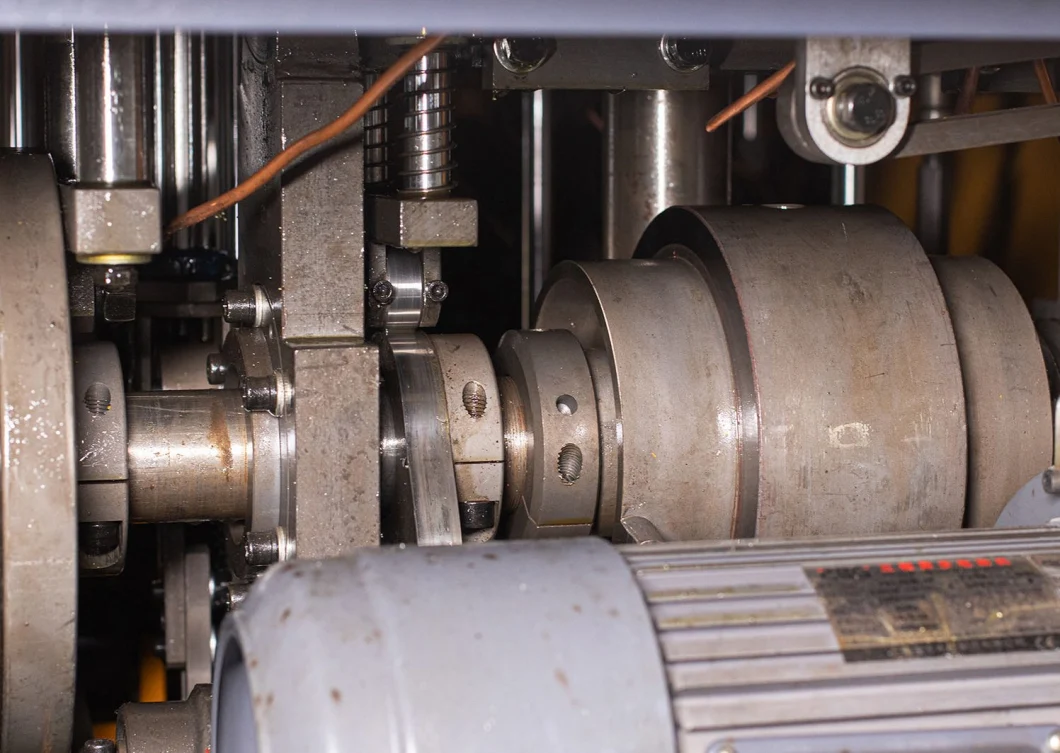

1. Machine Main part uses the Geneva open cam (as the picture New on left), instead of old dividing box transmission, makes driving more accurate, faster, and more reliable stability

2. Machine bottom is made by CNC machining, shaped in one-piece, the thickness is more than others' and heavier. It can improve the precision for each part, also help to stable the open cam long time running. The table also to be one piece, and completely closed design to make sure material can't go to driving system.

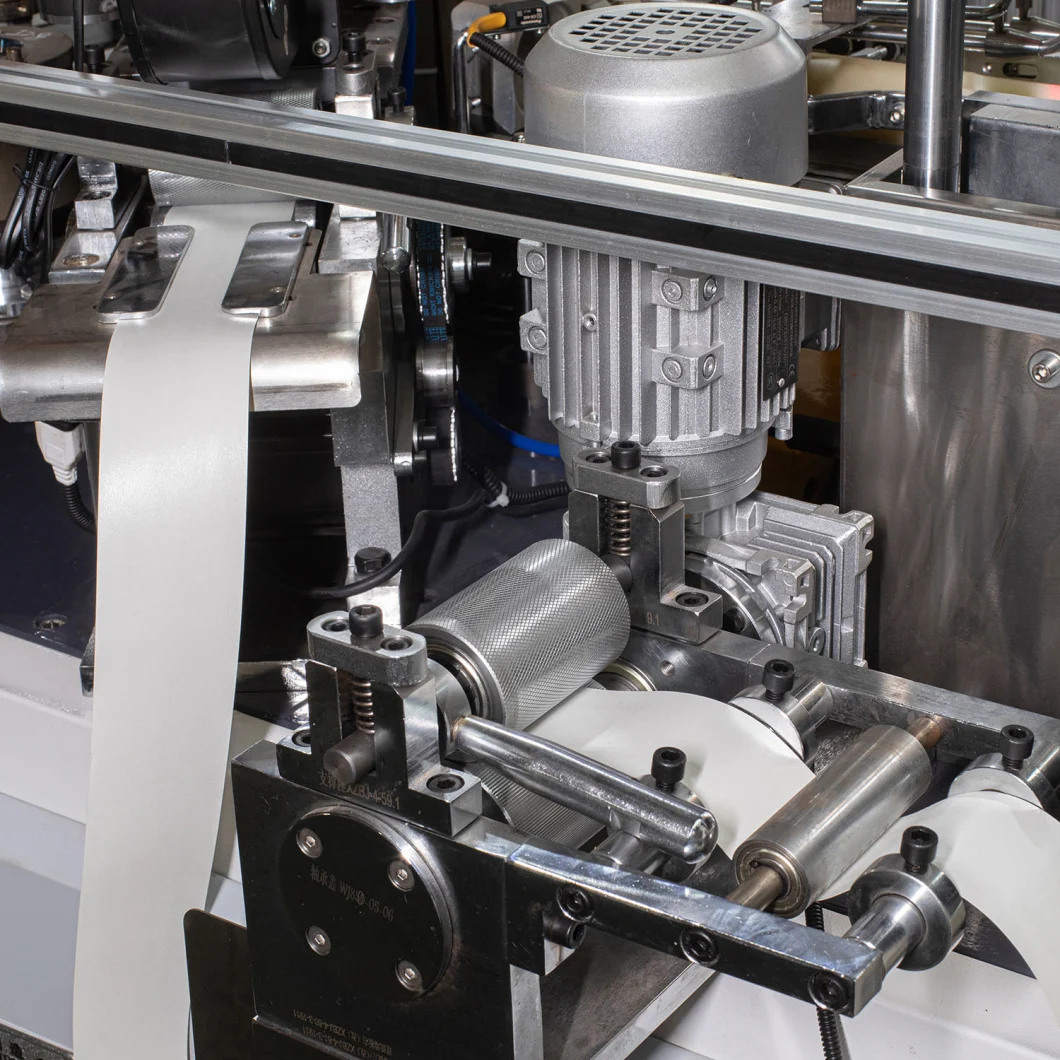

3. he sliding block is imported from Taiwan, instead of the old linear bearing design, this block has a long lifetime, and high precision.

4. The bottom paper feeding is adopted Two channel sending system, first use stepper motor transport, second adopt stepper motor precision feeding, to ensure accuracy and avoid waste. For old design, will have high waste also will produce much scraps of paper during production.

5. Bottom heaters we add the Hot air heating system, to form cup bottom at a short time and high quality.

6.This machine has automatic lubrication system, ensure the machine to keep long time running stably. The design of the oil pipe, can lubricate each point more accurately. We also add filter screen to keep the lifetime of oil core. Also this machine has oil pump and two valves, one valve for controlling the oil quantity, one is convenient to change oil.

7. The main motor with brake, can set the testing stop positioning, debugging positioning to be higher precision, also to ensure the safety of debugging person.

8. Imported electrical parts and PLC controlling, easy operation on touch screen, makes machine more intelligent.

D.OUR OTHER RELATED MACHINE

we also have middle speed paper cup machine,high speed paper cup machine,paper cup handle machine,paper bowl machine,paper cup die cutting machine,paper cup printing machine,paper plate machine etc.can provide you a full paper cup production line!

Packaging & ShippingE.PACKAGE DETAILS

our paper cup machine all package with strong woodencase,and also will send you a tool box,english manual and electric diagram with machine,also will send you a CD to teach you how to operate machine.

Our ServicesF.AFTER SERVICEE1. one year warranty

2.24 hours after service for technical support

3.provide free training

Company InformationG.FACTORY VIEW

FAQQ1.are you factory or trading company?

we are machinery factory and has 20 years experience.

Q2.where is your factory and how to get there?

our factory location is 7# yongding road,songjiadai industrial park,feiyun town,ruian city,zhejiang province.china

you can by plane from your country to wenzhou city airport,then we will pick you up by car.

Q3.what certification do you have?

we have CE,BV and SGS certification.

Q4.what is your delivery time?

Automatic High speed Paper Cup Making Machine Price need 25 -30 days in normal,if your order is urgent,we can discuss about that.

If you are interested in our paepr cup machine prodcution line,

pls do not hesitate to contact me!

Our Contact