Automatic 6000bph Bottle Drinking Water Washing Filling Capping Machine

Description

Basic Info

| Model NO. | VACGF-6000 |

| Feed Cylinder Structure | Single-Room Feeding |

| Dosing Device | Surface Type |

| Filling Principle | Normal Pressure Filling Filling |

| Packaging Container Lifting Structure | Chute Lifting |

| Structure | Rotary |

| Packaging | Bottle |

| Packaging Material | Plastic |

| Capacity | 6000bph for 500ml |

| Bottle Size | 200ml-2000ml |

| Main Material | SUS304 |

| Bottle Material | Plastic |

| Cap Material | Plastic Screw Type |

| Filling Valve | Normal Pressure Filling Valve |

| Temperature | Normal Temperature |

| Pump | Cnp |

| PLC | Mitsubishi |

| Electrial | Famous Brand |

| Washing Heads | 18 |

| Filling Heads | 18 |

| Capping Heads | 6 |

| Bottle Enter | by Air Conveyor |

| Bottle out | by Conveyor |

| Transport Package | Wooden Case |

| Specification | 15CBM |

| Trademark | GM |

| Origin | Zhangjiagang |

| HS Code | 8422301090 |

| Production Capacity | 10sets/Year |

Product Description

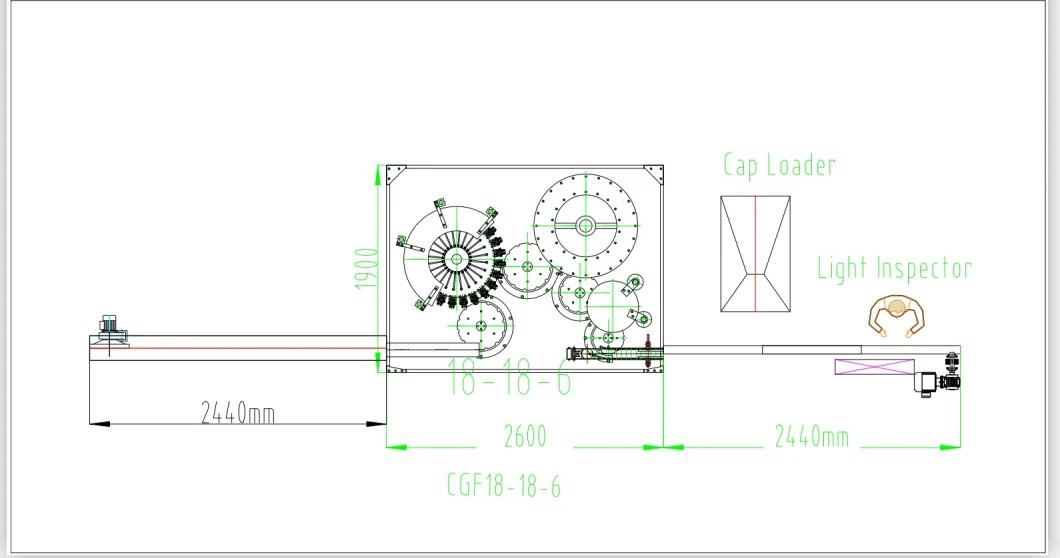

Automatic 6000BPH bottle water washing filling capping machine/ filling 3in1 machine/monobloc

VACGF-6000 model of bottled water filling monobock for plastic pet container , the machine with functions of washing filling capping 3in1 in one body.

the machine works auotmatically , controlled by PLC, operate is easy by touch screen . the mainly material adotps high quality sus304.it is idea machine for kinds of water ,beverage factory . the bottles size from 200ml-2000ml ,it just need to change the wheel-start for different volume of the bottles.

Product Parameters

| washing heads | 18 |

| filling heads | 18 |

| screw capping heads | 6 |

| mainly motor power | 2.2kw |

| suitable bottle | plastic 200-2000ml |

| theory capacity | 6000-7500bph for 500ml |

| dimension | about 2600x2100x2100mm |

| weight | about 2550kg |

Beverage Machinery-Equipment characteristics:

1. Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change of the bottle-shaped become easier.

2. Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough..

3. The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

4. High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

5. Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

6. Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's Mitsubishi, famous brand

7. Equipped with a constant temperature system, temperature controlled and circumfluenting automatically.

flow chart

air conveyor for feeding bottles ->bottle washing->bottle filling ->screw plastic capping ->lighe inspetion ->cap loading

Project in the world

vietnam/russia/india...

Main configuration

main parts of filling machine

| pump | cnp |

| plc | mitsubishi |

| touch screen | china taiwan brand |

Detailed Photos

Certifications

VR of factory

https://world-port.made-in-china.com/viewVR?comId=IohnWkpGqAiz

GM23-0020

Our Contact